New fermentation technology improves bioethanol production

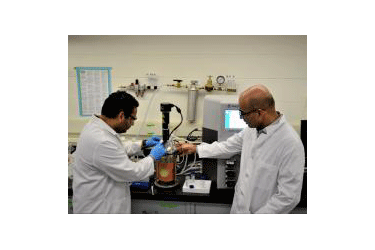

URBANA, Ill. - Research at the Integrated Bioprocessing Research Laboratory (IBRL) at the University of Illinois continues to improve the dry-grind process used to produce ethanol from corn.

“One of the major challenges in the dry-grind process is use of high corn solid loadings needed to achieve high ethanol concentrations and make distillation more economical,” says Vijay Singh, director of IBRL and a professor in the U of I Department of Agricultural and Biological Engineering.

Use of high solids reduces heat demand for drying of DDGS (co-product from the process), lowers the capital cost due to smaller size equipment, and decreases water use for slurry preparation. Together with Deepak Kumar and Ankita Juneja, both postdoctoral research associates in agricultural and biological engineering at U of I, Singh is studying the use of increased corn solids in this process.

In the dry-grind process, corn starch in the solids is converted to glucose, and the glucose is fermented by yeast to produce ethanol. However, too much ethanol built up during fermentation inhibits the yeast, and it can no longer efficiently convert the sugar into alcohol. “The typical dry-grind corn process uses a slurry [ground corn mixed with water] consisting of 30 to 33 percent corn solids,” Kumar says. “We increased the corn solids up to 42 percent.

“Of course, with high solid concentration comes high ethanol build-up in the fermenter,” Kumar adds. “We use an intermittent vacuum flashing process to remove some ethanol from the fermentation tank as it is produced. This keeps the ethanol concentration below the inhibitory levels and allows complete fermentation of corn solids up to 42 percent. Use of vacuum allows ethanol evaporation at the normal fermentation temperatures (32–34 degrees C), without affecting the yeast health. The vacuum-assisted fermentation resulted in 88 percent higher conversion efficiency than the conventional process.”

The research team also applied this technology to the dry-grind process at normal corn solid loadings of 32 percent. “Under normal conditions, fermentation of 32 percent solids can take anywhere from 48 to 72 hours,” Kumar explains. “However, applying the vacuum-flashing technology under optimum conditions resulted in complete fermentation in only 32 hours.”

That is twice as fast as the conventional process, Kumar notes, “which would allow existing plants to process more material with the same equipment, and new plants could use smaller fermentation tanks. Both would lead to lower capital and operating costs.”

Singh adds, “It’s important to note this is the first time 42 percent solids have been used in this process, and no additional enzymes or yeast nutrients were added [compared to the conventional process], so this was accomplished without increasing process inputs.”

Singh and Kumar are working on developing process models to perform a detailed techno-economic evaluation of the process to determine the benefits of using the technology on a commercial scale.

The paper, “Fermentation technology to improve productivity in dry grind corn process for bioethanol production,” is published in Fuel Processing Technology. Co-authors include Deepak Kumar, Ankita Juneja, and Vijay Singh. Their work was partially supported by the Center for Advanced Research in Drying (CARD), an NSF-Sponsored Industry-University Cooperative Research Center, jointly located at the Worcester Polytechnic Institute and the University of Illinois at Urbana-Champaign.